TiSIN Coating

TiSiN Coating – TiSiN (Titanium Silicium) Nitride is a coating with excellent hardness, bronze, high thermal and oxidation resistance. Incorporation of silicon to the coating results in the formation of nanocomposite system where nano-sized TiN grains are embedded in amorphous a-SiNx matrix. This typically coated on high speed cutting tools used on CNC machines for machining of hardened steels from 50 to 65 HRC.

TiSiN coating is suitable especially for monolithic hard metal milling cutters, drills, inserts and shaping knives. It can be used in dry or near-dry machining applications for machining process.

TiSIN Coating Data

- Hardness : 35 GPa

- Thickness : 1 – 4 micrometers

- Coefficient of friction : 0.6

- Thermal stability : 1100°C

Influence of Coatings on The Properties of a Tool for Machining Process

- Prolonged toll lifetime

- Reduce down-time

- Reduce tooling costs per piece

- Decrease the coefficient of friction

- Increase the surface hardness

- Increase the temperature stability of the tool tip

- Increase the oxidation and chemical resistance

- Allow machining of hardly workable materials

- Allow increased feed and speed rates

- Decrease cutting forces

- Decrease roughness of the machined surfaces

- Decrease material sticking

- Minimalize the amount of cooling liquid used and allow even dry machining

- Substantial cost reduction

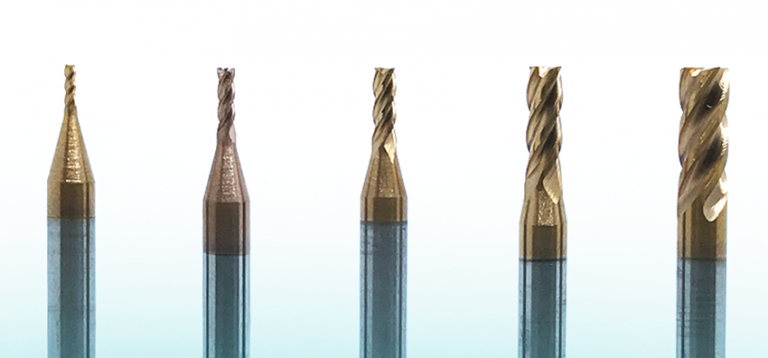

Hanzel 50 HRc Carbide End Mill with TiSIN coating

For your excellent machining process, Hanzel have Carbide Endmill Gecko series with TiSIN coating.

- Coating Color: Bronze

- Good for working on materials: Carbon Steel, Allumunium, Alloy Steel, Stainless Steel, Hardened Steel up to 55Hrc

- Available Shape: Ball Nose, Square

- Number of Flutes: 2 Flutes (Ball Nose), 4 Flutes (Square)

- Tool Length: Short, Extra Length

Ready to Decide on an End Mill with TiSIN Coating?

Hanzel Technical Support: +62 812-3458-8903

Instagram: @hanzeltool

Hanzel 65 HRc End Mill Blizter Series

Hanzel 65 HRc End Mill Blizter Series  Hanzel 45 HRc End Mill Epix Series

Hanzel 45 HRc End Mill Epix Series  Hanzel 55HRc End Mill Gecko Series

Hanzel 55HRc End Mill Gecko Series