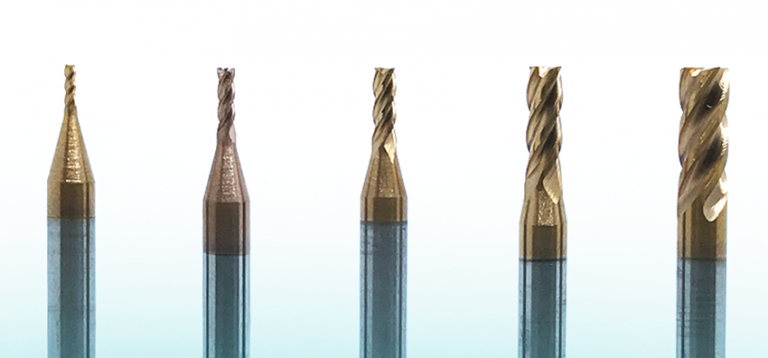

Roughing, Finishing, Flat, Ball Nose, Corner Radius End Mill

Roughing End Mills

These mills have scallops on the outside diameter which causes the metal chips to break into smaller segments. This results in lower cutting pressures at a a given radial depth of cut. They are mainly used to rough mill the material off when large amounts of material are removed. They come in carbide, cobalt, and HSS substrates, and are often PVD coated with AlTiN or ZrN. They come in fine, medium and coarse pitch scallops. They come in stub, standard, long, and extra long lengths. There are many different helix angles, and flute configurations, because of the many different materials being milled. They come in a wide variety diameter sizes from 1/8″ to 3″.

Finishing End Mills

A finishing end mill has one square end and the outside diameter is smooth for creating smooth surface finishes. They come in a variety of helix angles and numbers of flutes. They are mainly used for facing or side milling operations.

Square End Mill or Flatt End Mill

Square end milling cutters are also known as a “flat end mills”. The corners of these mills are sharp and generate a 90° angle. They can be single end or double end and they can be made from solid carbide or various compositions of high speed steel. Carbide square end mills are the most productive. They can be general purpose or high perfomance geometries. They can be used used for plunging, grooving, side milling, face milling, and counter boring. These are the most popular milling cutters in the industry. They are available in a wide variety of diameter sizes.

Ball Nose End Mill

A ball end milling cutter is also known as a “ball nose mill”. The end of this tool is ground with a full radius equal to half of the tool diameter, and the edges are center cutting. They can be single end or double end and they can be made from solid carbide or various compositions of high speed steel. They can be general purpose or high perfomance geometries. They can be used used for milling a large corner radius, grooving with a full radius, and contour or profile milling. The smaller diameters can be used for engraving. They are available in a wide variety of standard sizes and lengths.

Bull Nose End Mills (Corner Radius)

Bull end mills are simply corner radius end mill cutters. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder. Corner radius end mill cutters have a stronger milling edge than square end mills, so feed rates may be increased and yield longer tool life and greater productivity. These milling bits may also be used in mold profiling applications with greater productivity than ball end mills. These mills are all solid carbide, and are available in many diameter sizes and lengths.

Ready to Decide on an End Mill with TiSIN Coating?

Hanzel Technical Support: +62 812-3458-8903

Instagram: @hanzeltool

Hanzel 65 HRc End Mill Blizter Series

Hanzel 65 HRc End Mill Blizter Series  Hanzel 45 HRc End Mill Epix Series

Hanzel 45 HRc End Mill Epix Series  Hanzel 55HRc End Mill Gecko Series

Hanzel 55HRc End Mill Gecko Series