Differences Beetween Conventional and Climb Method during Milling Process

There are two methods to cut materials when milling process: Conventional Milling and Climb Milling. The difference between these two techniques is the relationship of the rotation of the cutter to the direction of feed.

- Conventional Milling, the cutter rotates against the direction of the feed.

- Climb Milling, the cutter rotates with the feed.

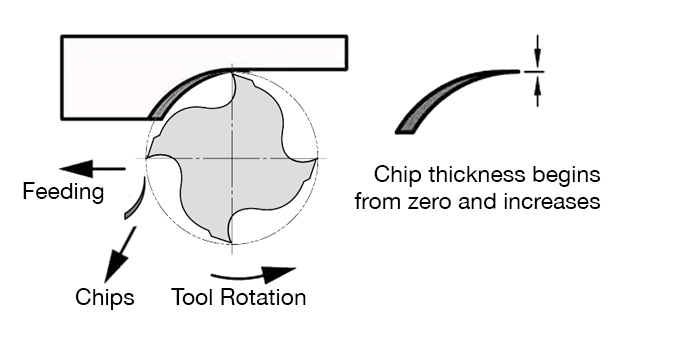

Conventional Milling Method

- Chip width starts from zero and increases which causes more heat to diffuse into the workpiece and produces work hardening

- Tool rubs more at the beginning of the cut causing faster tool wear and decreases tool life

- Chips are carried upward by the tooth and fall in front of cutter creating a marred finish and re-cutting of chips

- Upwards forces created in horizontal milling* tend to lift the workpiece, more intricate and expansive work holdings are needed to lessen the lift created*

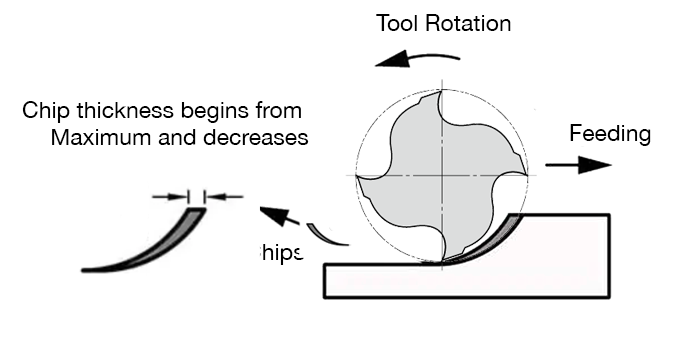

Climbing Milling Method

Chip width starts from maximum and decreases so heat generated will more likely transfer to the chip

Creates cleaner shear plane which causes the tool to rub less and increases tool life

Chips are removed behind the cutter which reduces the chance of recuttingDownwards forces in horizontal milling is created that helps hold the workpiece down, less complex work holdings are need when coupled with these forces

Horizontal milling is when the center line of the tool is parallel to the work piece

Hanzel 65 HRc End Mill Blizter Series

Hanzel 65 HRc End Mill Blizter Series  Hanzel 45 HRc End Mill Epix Series

Hanzel 45 HRc End Mill Epix Series  Hanzel 55HRc End Mill Gecko Series

Hanzel 55HRc End Mill Gecko Series